Reinhard Backhausen is a thought leader in the circular economy and advises renowned companies worldwide, and specialises in the textile industry. Syngroup Managing Director Walter Woitsch opens the conversation with him, with a simple case: A men’s cotton shirt weighs about 20 dag and we assume it costs 80 euros today. Currently, the price for 1 kg of cotton on the world market is about 80 cents. On the other hand, the price per kilo for the shirts in our example is 400 euros.

With such impressive value add, where do the greatest levers for the more careful use of resources lie? In logistics? Work in progress, as cotton and other primary materials for various processing steps have travelled around the world at least once. What role does technology play and does the processing industry have any real influence? What is the role of politics, trade and consumers? What are currently the big issues that can accelerate or slow down the path towards a circular economy?

According to Reinhard Backhausen; first we have to distinguish between the big picture and the behaviour of the individual players. Companies are usually, simply overwhelmed and do not know how to tackle issues such as sustainability and the circular economy. For the expert, it is the task of politics to create the framework conditions and incentives that encourage entrepreneurs to support and promote the necessary changes. The European Green Deal announced by Ursula von der Leyen in 2019 is a milestone in this regard. A lot of what will happen in the future is already packed into this concept. Europe can play a pioneering role as long, “the big four” (China, USA, Russia and India) participate. A small country like Austria can focus these developments and act as a role-model, similar to what Holland already does.

Grants or tax relief would be an impetus to consistently develop a proper eco-design. From the very beginning, this involves answering the question of what should happen to a product at the end of its life cycle. How can it be recovered or recycled and how can all of the individual components be separated in order to recycleAustria is already well advanced in this field, Reinhard Backhausen states and refers to pioneering research at the Vienna University of Technology. The Institute of Process Engineering is researching and implementing the chemical processing of mixed textiles made of polyester and cotton and their possible re-use.

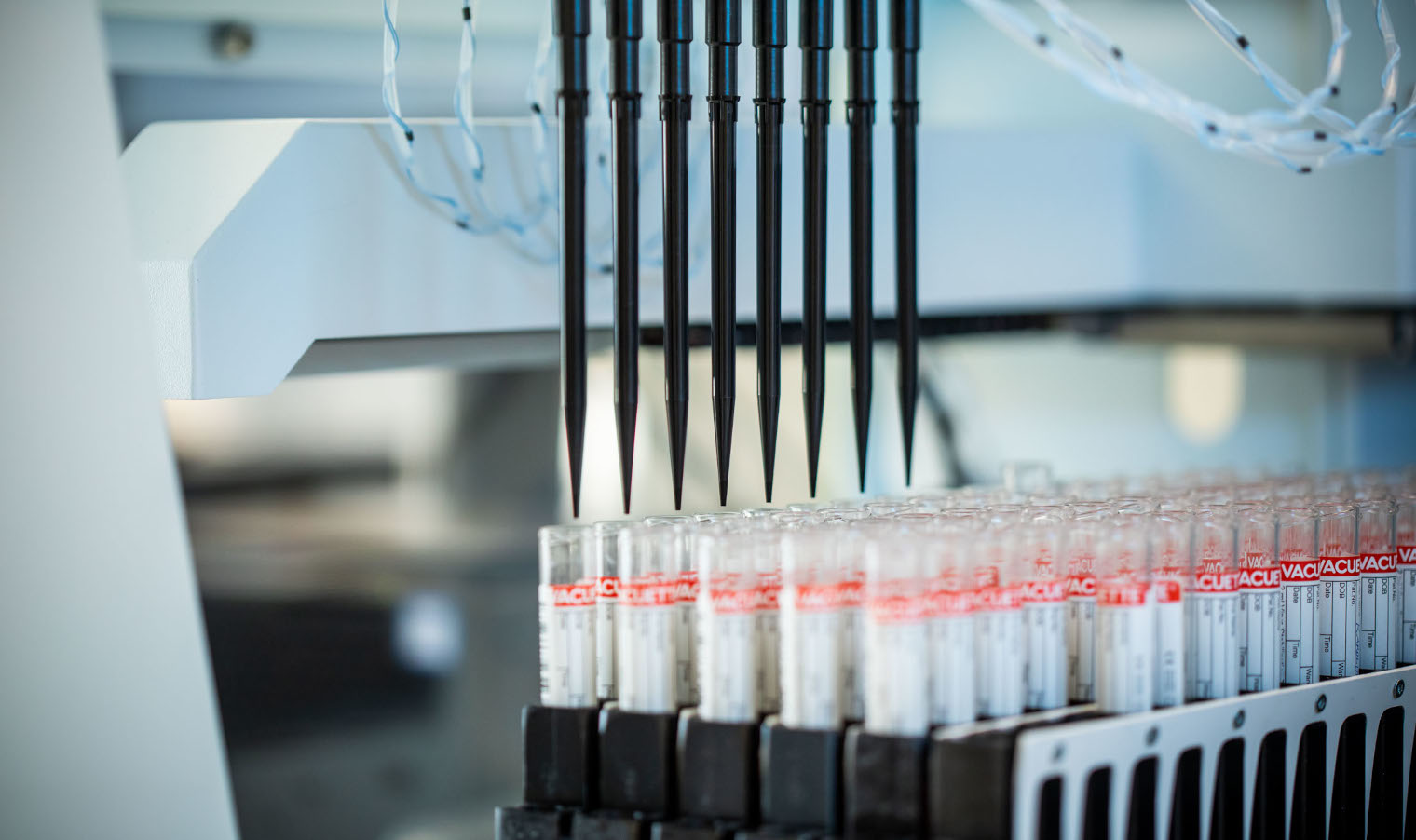

In addition to research and development, according to the expert, it is essential to lead companies towards new approaches, in order to make the added value of innovative concepts transparent by means of role models in economic practice. Backhausen points to Brantner Green Solutions as an example. In the area of waste and resource management, the company relies on the use of intelligent technologies such as artificial intelligence, sensors, robotics and telematics. Imaging systems, for example, support the separation and sorting of waste.

Backhausen is convinced that the “polluter-pays“ principle applies to environmental issues. The greatest responsibility lies with the manufacturers, who have to convince the retailers, who in turn have to communicate it conclusively to consumers. The guidelines must come from politics and it is the obligation of everyone to follow suit. “It has to get into people’s heads! This also requires uniform, comprehensible eco-labels, such as those used for food. Among the 400 eco-labels currently available, there is also one from the European Commission, but it is not currently being used. The goal must be to achieve a cradle-to-cradle system that follows the natural principle of cycles without waste in all areas – environmentally friendly production, renewable energies, technical and biological cycles and social standards.

The technological implementation is up to the processing industry, especially mechanical engineering. There are promising approaches to make fibres out of PET, biodegradable again. “There is sweet music in that. If synthetic fibres can be made biodegradable, it will be exciting,” says Backhausen. The technology must become accessible to everyone, because if I can return everything to the cycle, ‘intelligent waste’ becomes possible. Natural resources will not suffice. Intelligent technologies are needed in combination with the reduction in all areas.

Today, only a small proportion of finished fabrics and textiles are sent to or sold at the end of the first life cycle for further use or reuse, which is hardly traceable and uncoordinated and in small units. This has to happen in a more focused way, says Reinhard Backhausen: “The challenges are great, because a lot of composite materials end up in the containers. The technology will change a lot in the next 5 to 10 years, key words being artificial intelligence and recognition systems. But above all, we have to leave the throwaway society behind us.” First and foremost, the responsibility lies with the manufacturers, the circular economy expert warns. Backhausen established the cradle-to-cradle (C2C) philosophy early on in his company. For manufacturers, it would also mean taking back products, supported by incentive systems, for example, with the aim of a more professional return to the recycling system. This requires a new business model in which consumers do not have to own a product but pay for its temporary use. In addition, more precise testing and labelling are needed so that buyers can influence their choice in a qualified manner, e.g. in the case of C2C-certified products.

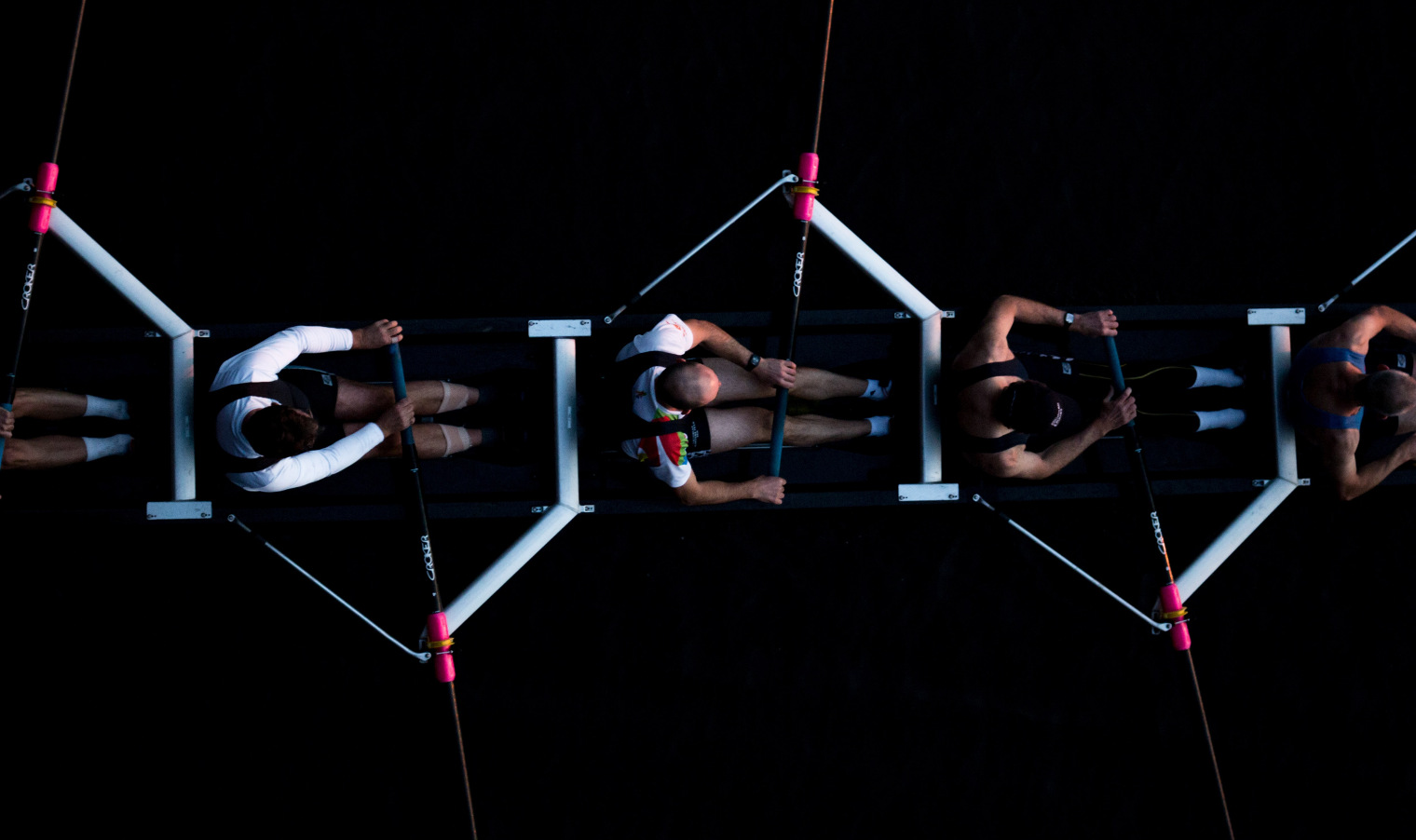

“Global co-operation is inevitable. Initiated by the retail sector, as a lot is produced for Europe in Asia. This makes us dependent on them and we have learned little from the pandemic. If we want to keep (residual) production in Europe, we have to bring back areas such as technology development in recycling areas and strengthen them here again. If production then becomes a little more expensive, does it really matter, in the grand scheme of things? Industry alone can’t do it, it only works in co-ordination with retail.

In the very long and multi-part value chain of the textile industry, only global co-operation can lead to this goal. “We have the chance to pull together here,” says Backhausen, adding that the lip-service and announcements of the biggest players – the slow shift of the USA to the European path in climate policy or the strict tightening of China’s climate targets – must be followed by actions. If we want to talk globally about climate change, the environment or supply chains, it will take an incredible amount of time that we no longer have. Humanity must show the will to act quickly – with all the consequences, including the willingness to change in all areas. It needs a mindshift change among consumers, with conditions for a changed framework and technological support.

Today, we are facing a huge transformation of the economy. Starting with industry and retail, it is important to take consumers with us. If politics create the framework conditions for this – then that’s good. But we must not wait for them, says Backhausen: “We are able to fly to Mars, but we are using intelligence in the wrong way. We need a future-oriented approach to raw materials and energy, not space trips. We have an obligation to do everything we can to ensure that the ship quickly corrects its‘ course. Unfortunately, we are not fast enough. Agile jets but sluggish aircraft carriers. Nevertheless, I am optimistic that the next generations will be more sensible and less wasteful.”

Until 2021, REINHARD BACKHAUSEN managed the traditional weaving mill of the same name for high-quality upholstery and curtain fabrics. He has been working intensively on the topic of circular economy since 2008 and established the “Cradle-to-Cradle” philosophy within his company. Also, with his consulting business, he advises renowned companies in the textile industry and other sectors worldwide and specialises in business development, marketing, strategy and the implementation of the circular economy.